Here is a summary of 12 of my projects not protected by a non-disclosure agreement (NDA). The majority of my industrial projects are protected by an NDA.

- 1 . Single Station Pin-on-disk tribometer simulating dynamic gait

- 2. Multistation Pin-on-disk tribometer (static load)

- 3. Biomechanics tools

- 4. Multiphasic elastohydrodynamic lubrication model for artificial hip joint

- 5. Total Knee Arthroplasty Recovery Monitoring Using a Wearable Device

- 6. Markerless motion capture – quantifying animal gait

- 7. Simulating contact mechanics and wear of a class III medical device

- 8. Metal additive manufacturing of biomimetic meta-biomaterials

- 9. Artificial Intelligence for medical data analytics

- 10. Intensity-based 2D-3D medical image registration

- 11. Medical Device Design

- 12. Microtextured prosthetic hip joints to improve longevity

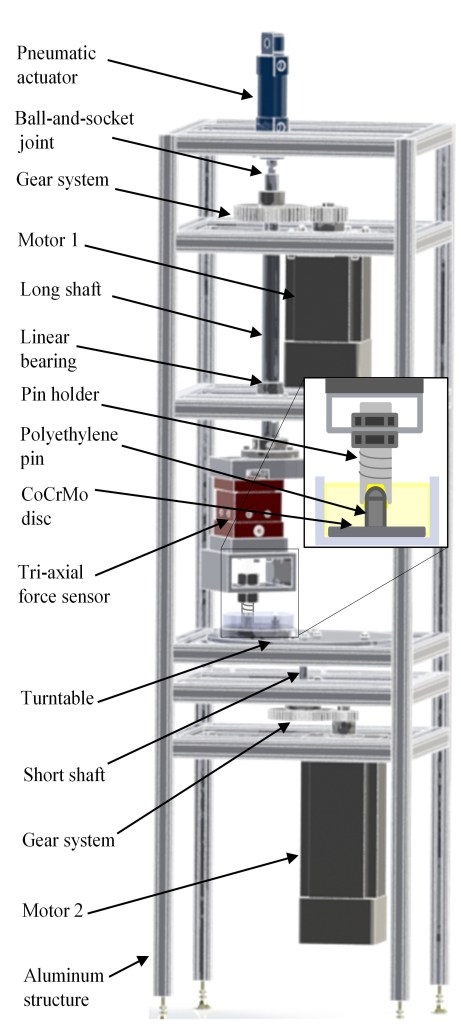

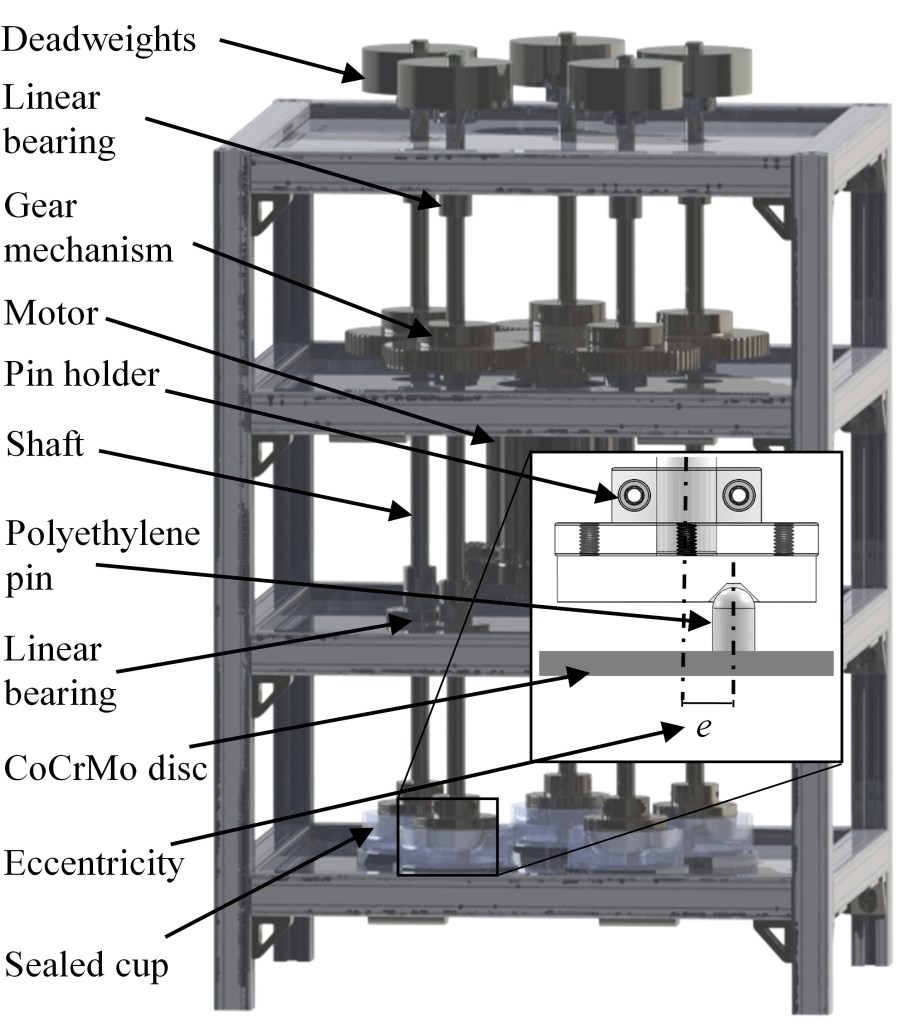

1 . Single Station Pin-on-disk tribometer simulating dynamic gait

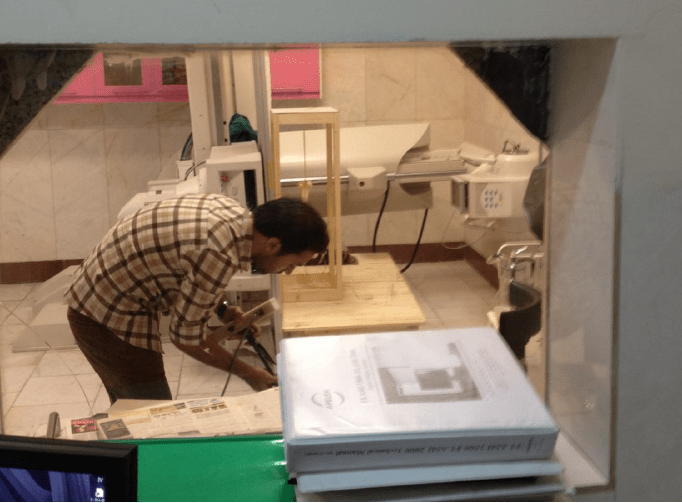

In this project, I designed and built a pin-on-disk tester capable of simulating any gait cycle

I designed and built a multidirectional Pin-on-Disk tester capable of applying dynamic loading to simulate the gait cycle. Tribometers are used regularly in the medical field for evaluating materials’ wear and friction.

This device had two servo systems including motion and force control systems synchronized together. An adaptive controller was used to control this device using xPC target for real-time data acquisition. A graphical user interface (GUI) was also developed to make interaction with the device easy.

Category:

Gait Simulation, Electro-Mechanic System, Robotics, Design, GUI, Real-Time Data Acquisition, Motion Planning, System ID

Toolbox:

LabView, C++, Matlab (SpeedGoat), SolidWorks, Waterjet CNC, Lathe-mills, CAD/ CAM, DMFA, Control, GD&T,

2. Multistation Pin-on-disk tribometer (static load)

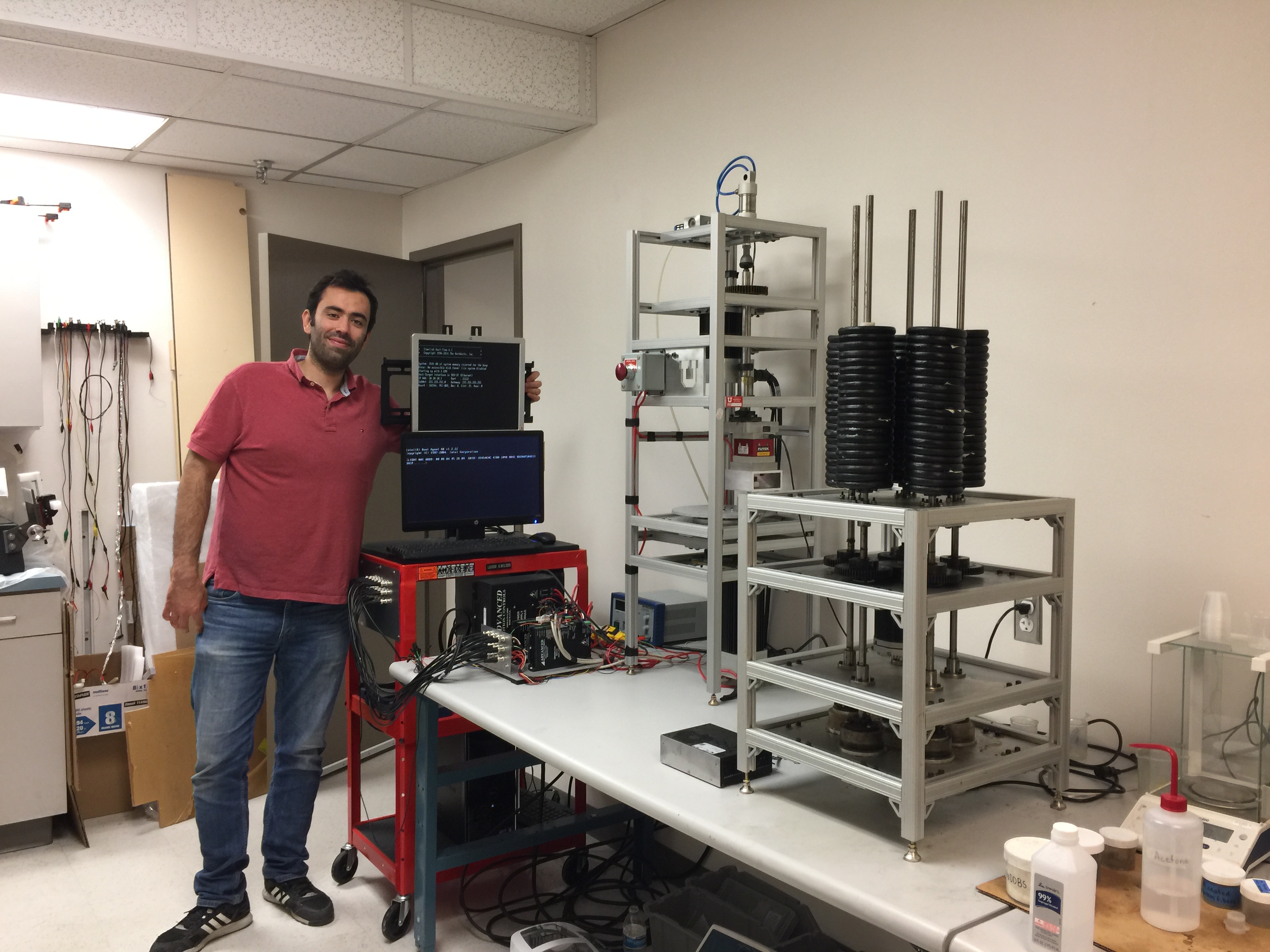

In this project, I designed and built a pin-on-disk tester capable of simulating static gait load

I developed a multistation pin-on-disk (PoD) tester to accelerate data collection for testing medical polyethylene. Polyethylene is a viscoelastic material; thus, wear experiments cannot be accelerated.

Unlike the first PoD tester, which can implement any user-specified wear path, this PoD tester only follows a circular wear path and applies static loading. I also used embedded hardware programming to simplify control for this system.

Category:

Gait Simulation, Electro-Mechanic System, design, GUI

Toolbox:

Embedded Hardware Programming, C++, SolidWorks, CNC, Lathe-mills, CAD/CAM, DFMA, Design Control, GD&T

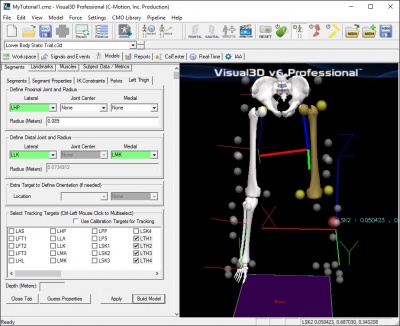

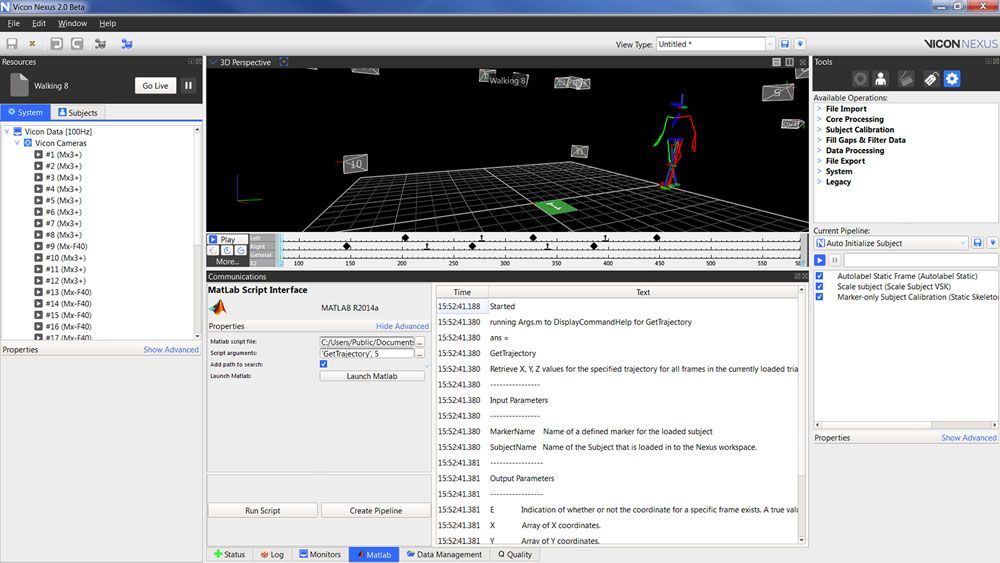

3. Biomechanics tools

I possess hands-on experience with various biomechanical tools that have widespread applications across multiple projects. These tools comprise 3D motion capture (marker and markerless), instrumented treadmill, IMU, Force Plates, Pedar, High-Speed Cameras, DIC, ECG, and EMG.

I am proficient in utilizing Matlab, Python (both traditional methods and novel AI methods for analyzing data), LabView, Vicon Nexus, and Visual3D.

More specific recent projects are protected under non-disclosure agreements.

Category:

Biomechanics tools

Toolbox:

Vicon Nexus, Visual3D, Matlab, IMU, ECG, EMG, Instrumented Treadmill, Python, LabView, Pedar, Digital Image Correlation

4. Multiphasic elastohydrodynamic lubrication model for artificial hip joint

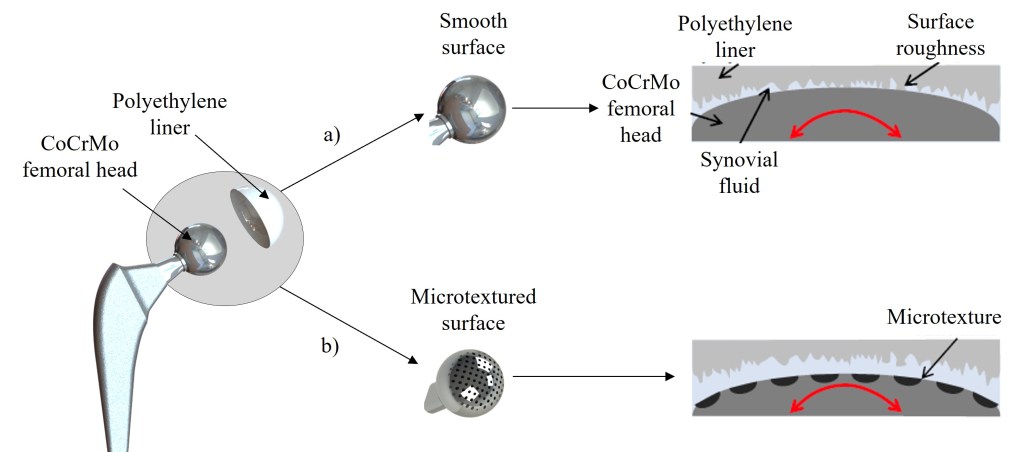

In this project, I used finite element analysis to simulate the lubrication mechanism in a textured artificial hip joint

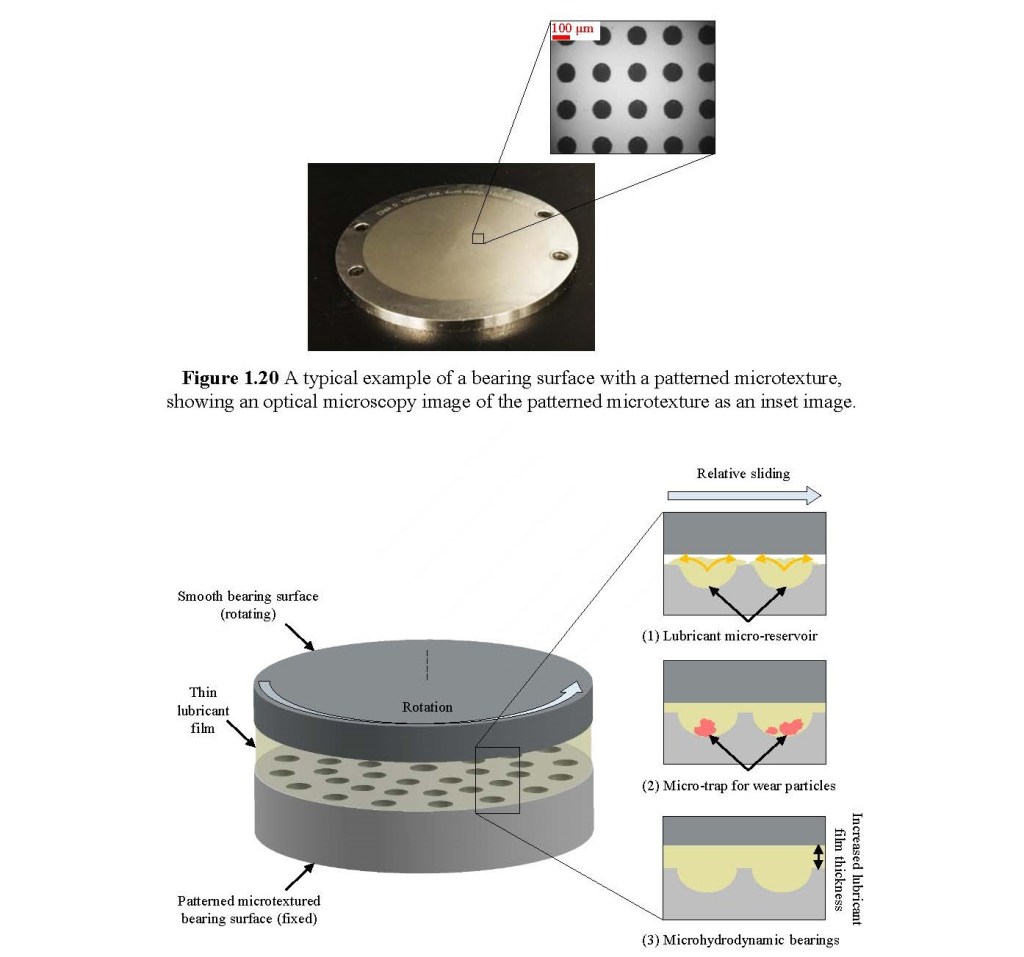

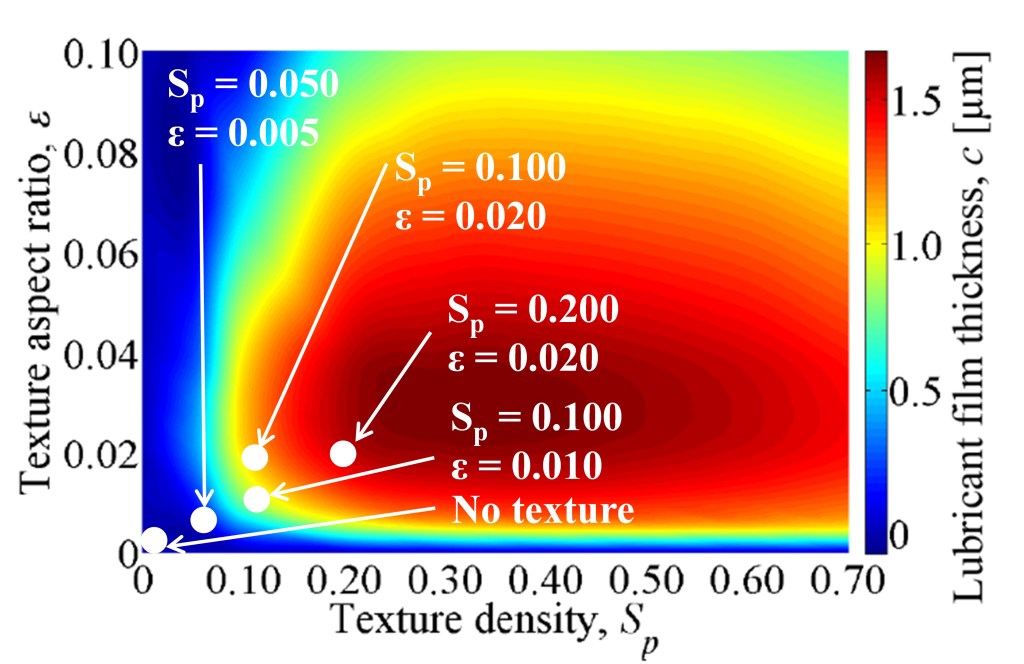

Adding a patterned microtexture to the smooth femoral head of a prosthetic hip implant increases the lubricant film thickness, which increases the separation between the two bearing surfaces. This increased lubricant film thickness reduces the likelihood of asperity-to-asperity contact, which in turn reduces wear. In this project, I used finite element analysis to simulate the lubrication mechanism in a textured hip implant and use this model to optimize the texture design to maximize lubricant film thickness.

Category:

Finite Element Analysis, Biomechanic Simulation

Toolbox:

Ansys Workbench, Python, Multi-Phasic, Non-Linear Materials, Fluid- Structure Interaction

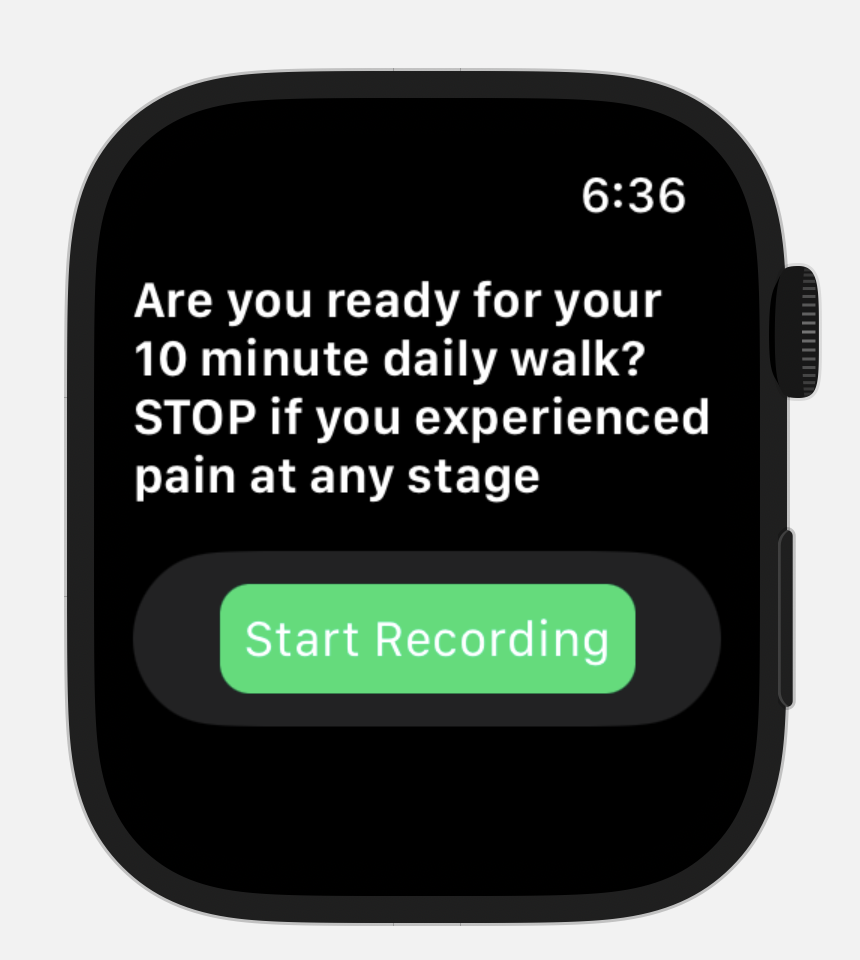

5. Total Knee Arthroplasty Recovery Monitoring Using a

Wearable Device

In this project, I developed a wearable and accompanying Apple Watch app to monitor knee replacement patients’ recovery.

Trauma or degenerative joint diseases can affect the structure of the knee joint and deteriorate its function, causing pain and disability. Post total knee replacement (TKR) clinicians monitor the patient’s progress and especially gait to evaluate the success of the surgery. The goal of this project was to design a wearable device that patients can wear on their normal knees to track their progress post-TKR surgery. I used a myriad of machine learning algorithms to analyze the IMU data and report back the results

Category:

Biomechanics, Gait Analysis, Machine Learning, Markerless Motion Capture

Toolbox:

IMU, Python Machine Learning Library, iOS App Dev, DOE

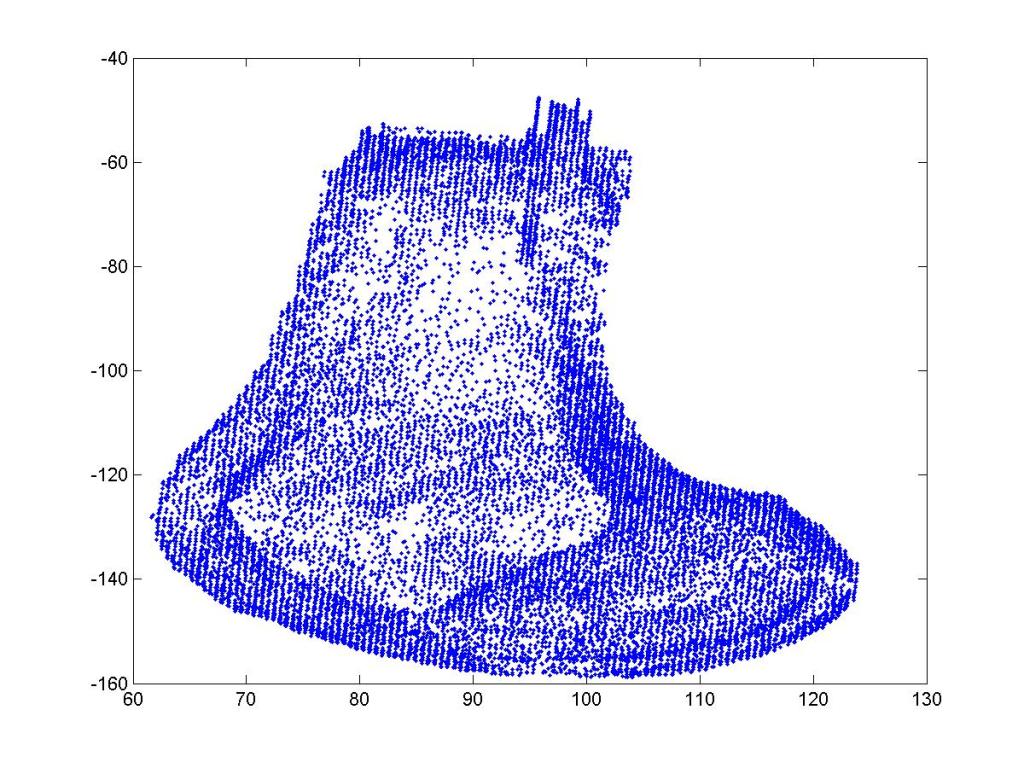

The blue dot indicates abnormal patella movement

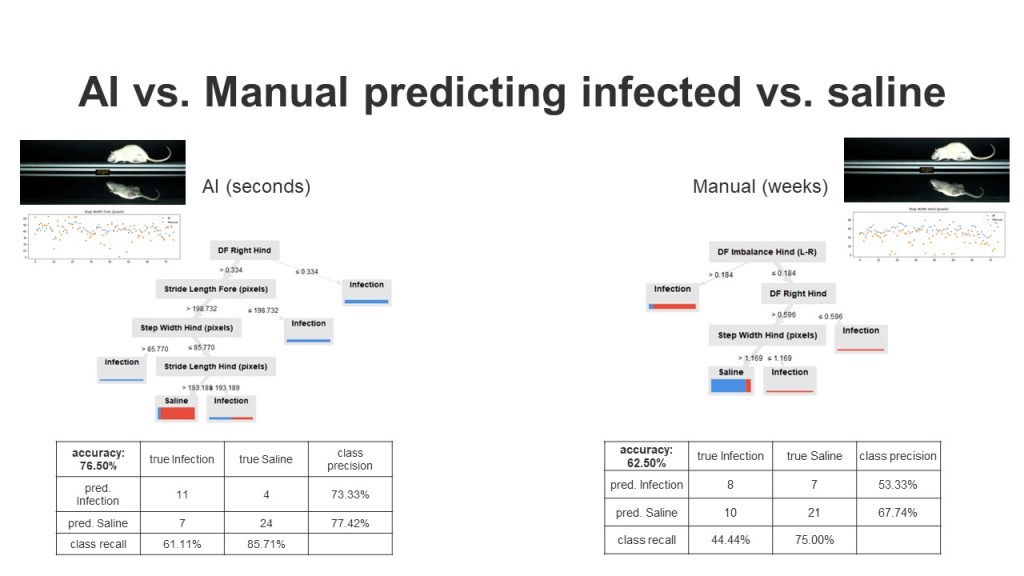

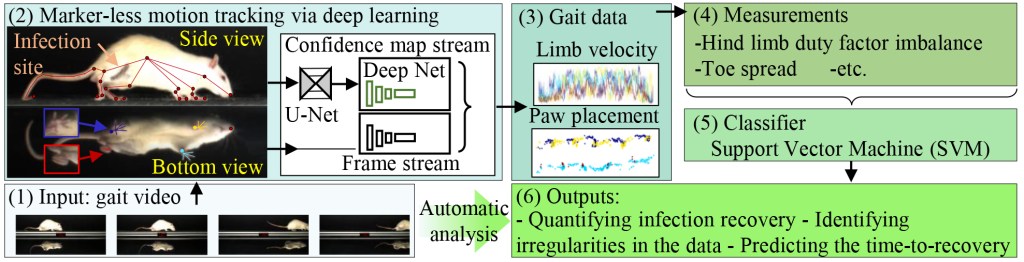

6. Markerless motion capture – quantifying animal gait

Traditional methods for tracking motion typically involve placing reflective markers on the body of the subject being studied. However, when working with animals, this approach can be difficult because animals often try to remove the markers by chewing on them, which can interfere with their natural movement patterns.

To overcome this challenge, in this project, I used a different technique called markerless motion tracking. This method does not require the use of physical markers but instead relies on deep learning algorithms to identify points of interest and track them. In this study, I quantified the gait of rats with orthopedic conditions through markerless motion tracking

Category:

Markerless Motion Capture, Gait Analysis, Deep Learning

Toolbox:

Tensorflow, Python, Gait Arena, High-Speed Camera

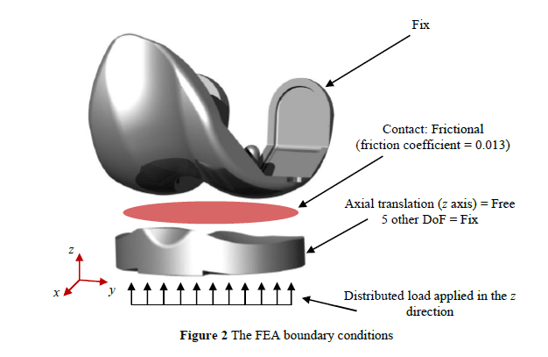

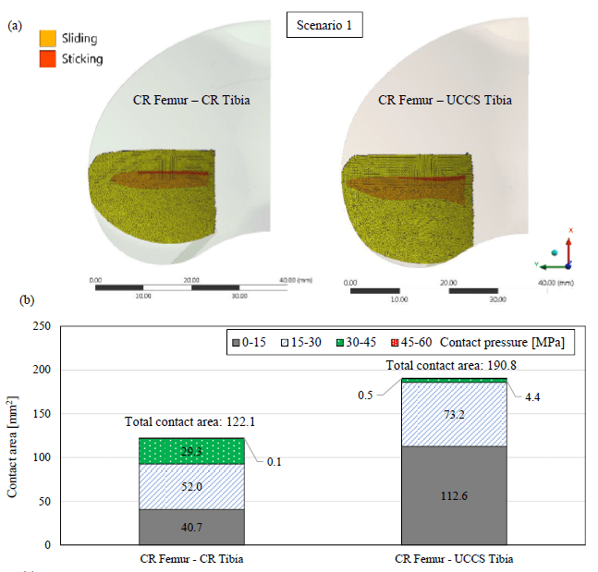

7. Simulating contact mechanics and wear of a class III medical device

This project was a six months contract with a major medical device manufacturer. I simulated the contact mechanics of an implant via FEA. I used an elastic-plastic material model to capture polyethylene deformation and optimized the design to reduce wear.

Category:

Finite Element Analysis, Biomechanic Simulation, Non-Linear Materials

Toolbox:

Ansys Workbench, Python

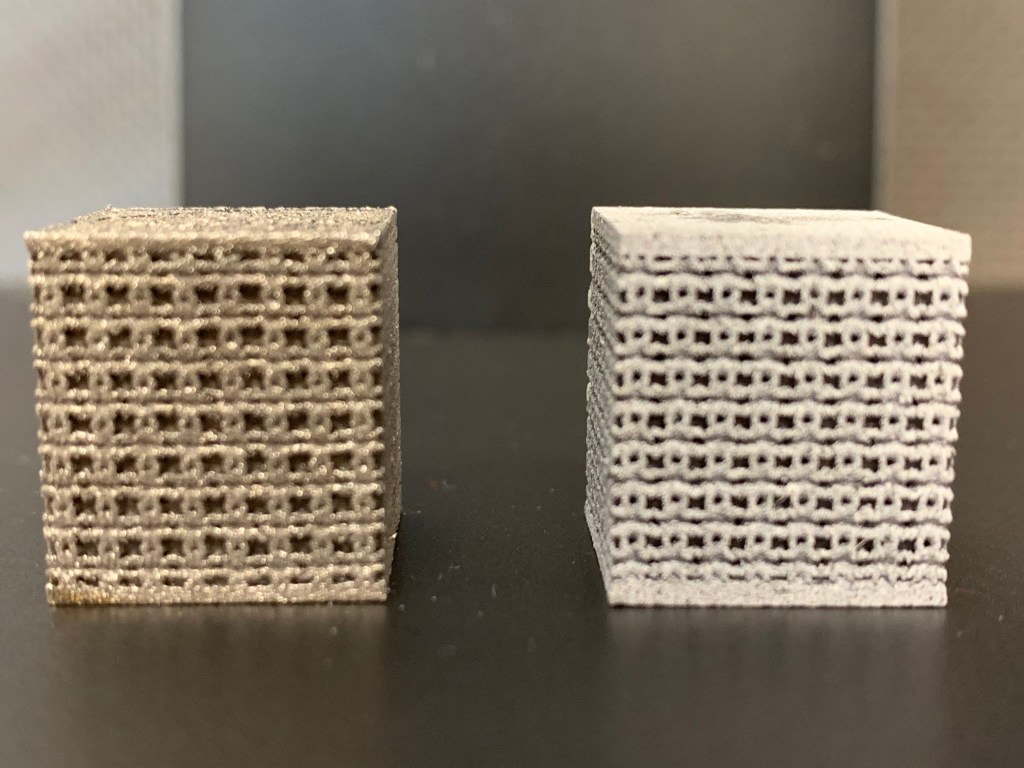

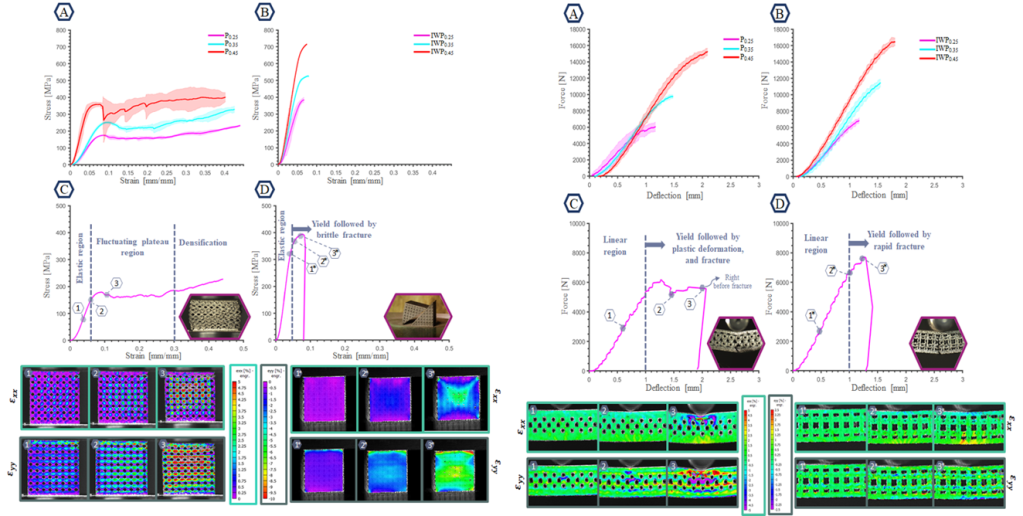

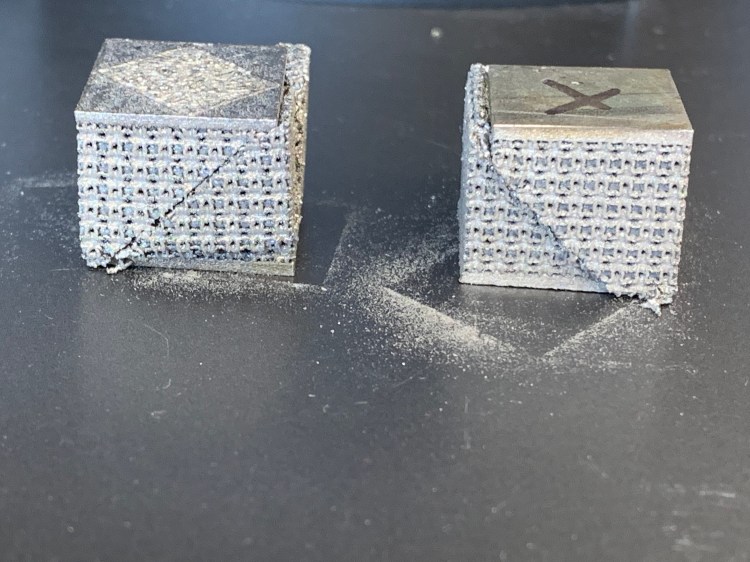

8. Metal additive manufacturing of biomimetic meta-biomaterials

This project aimed to develop new biomaterials that exhibited both the mechanical behavior of bone tissues at implant sites and mimicked their surface and morphological characteristics.

We designed, manufactured different biomimetic meta-biomatetrials. The morphological, quasi-static mechanical, and flexural properties of the designed meta-biomaterials were thoroughly evaluated

Category:

Biomimetic Material, Design, Material Characterization, 3D printing

Toolbox:

Mechanical Testing, Laser Powder Bed Fusion, Digital Image Correlation

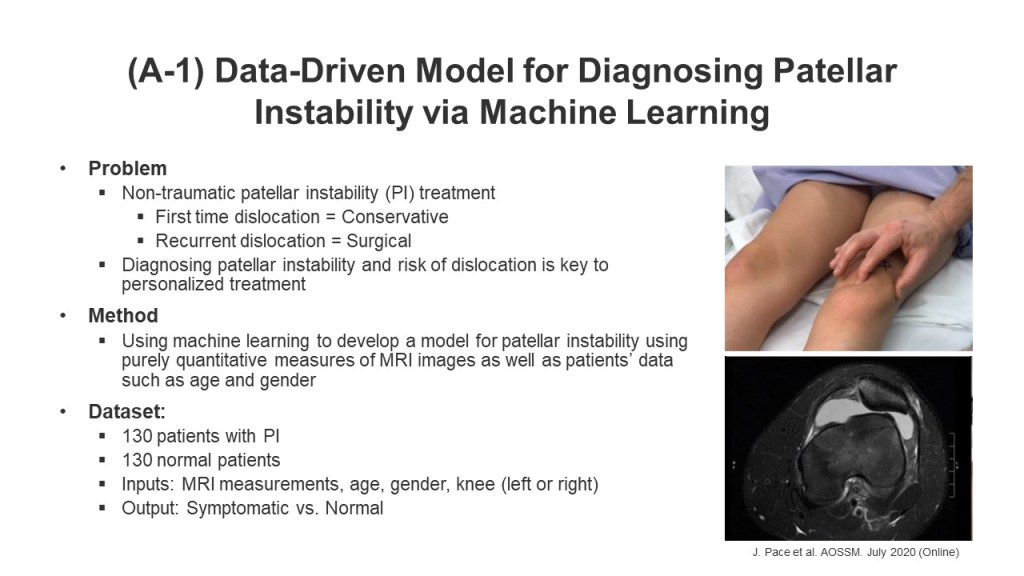

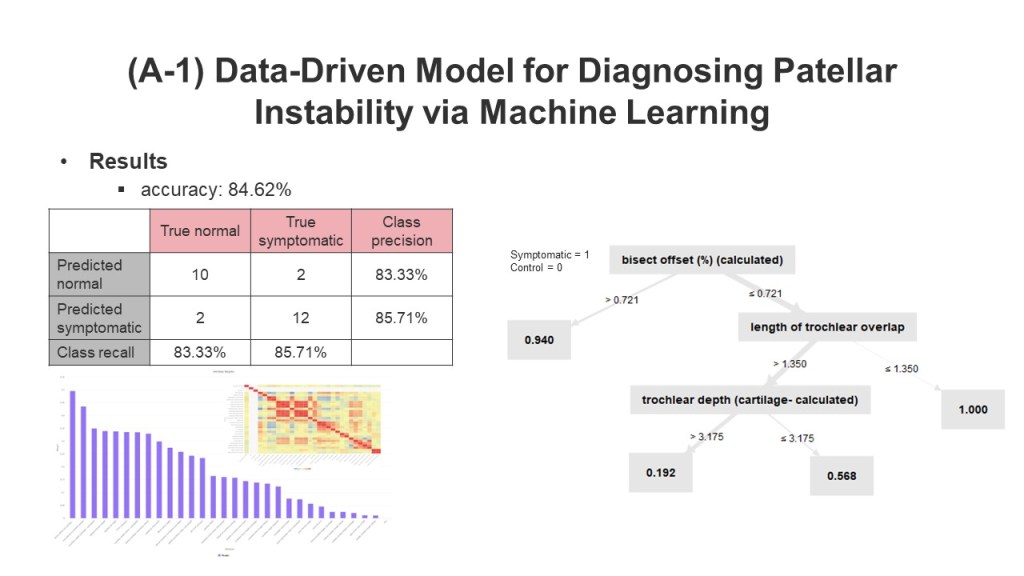

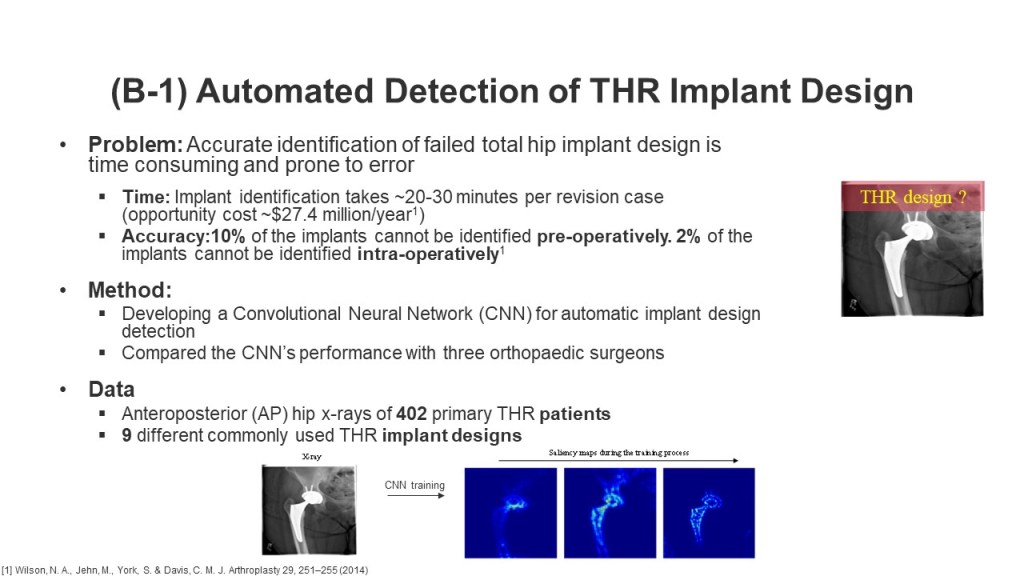

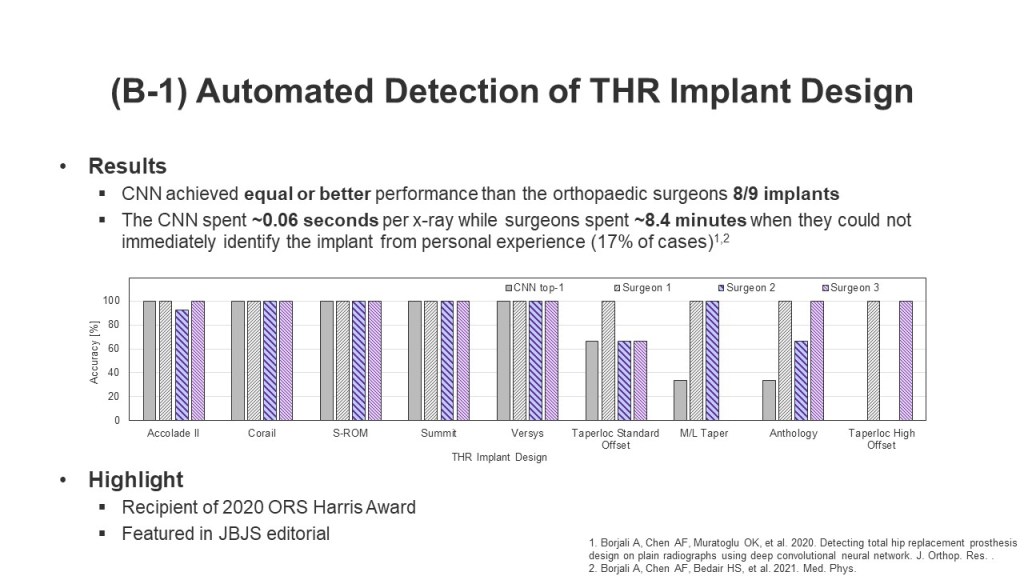

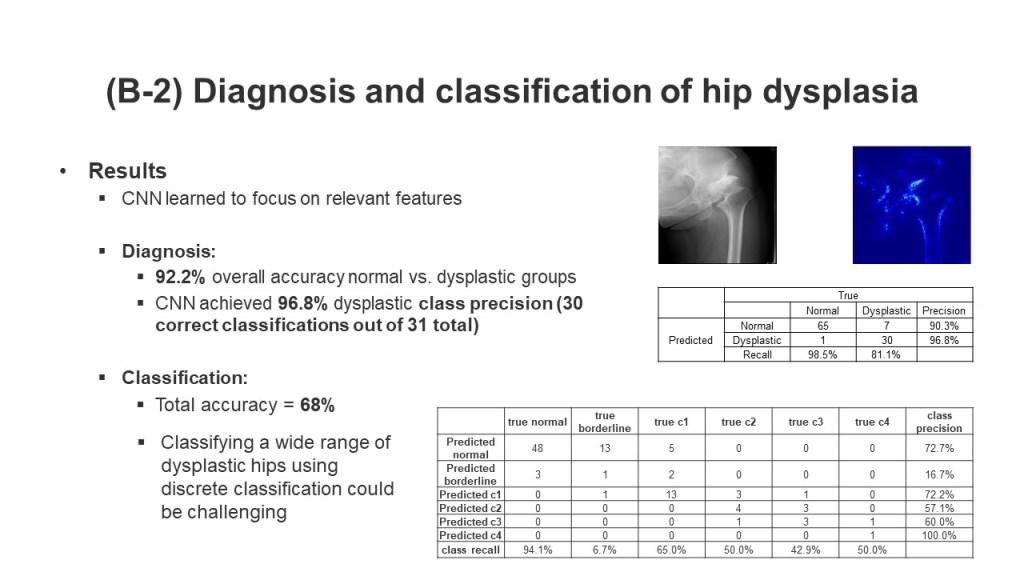

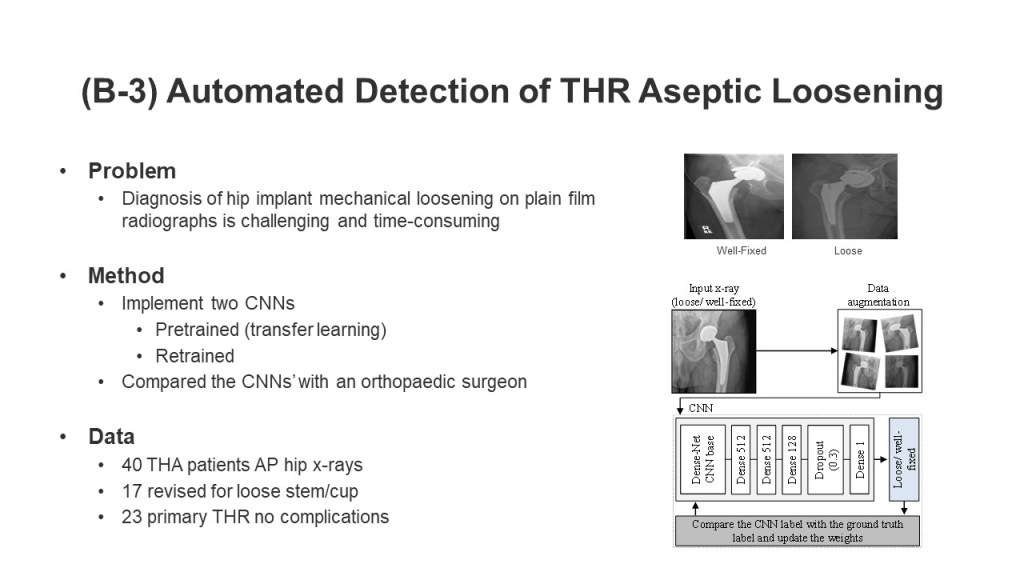

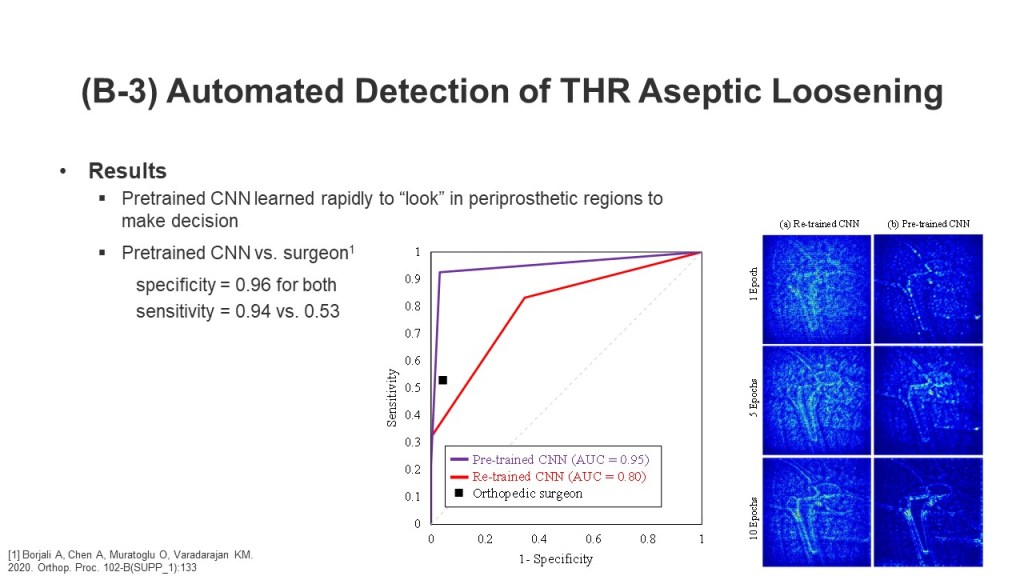

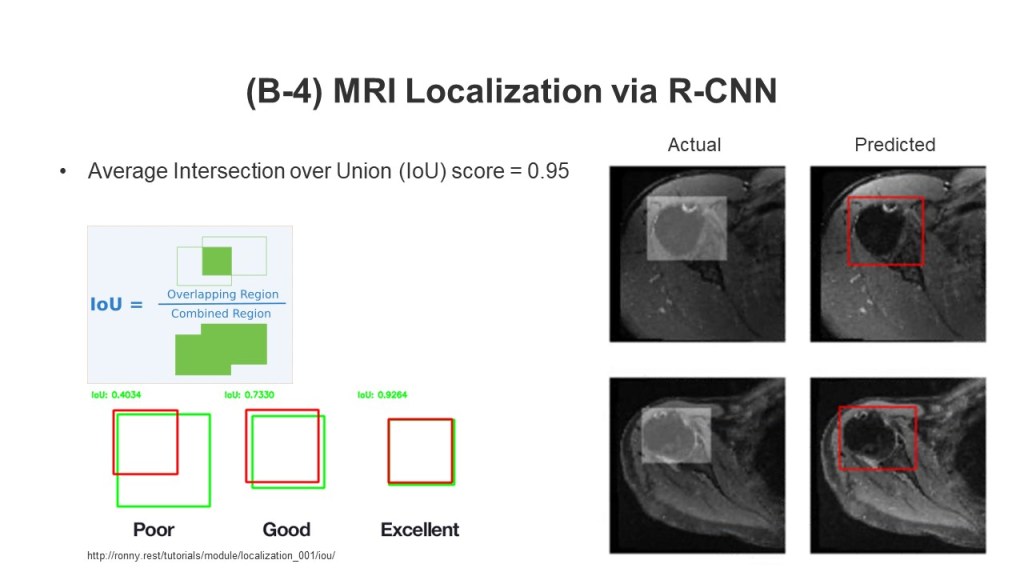

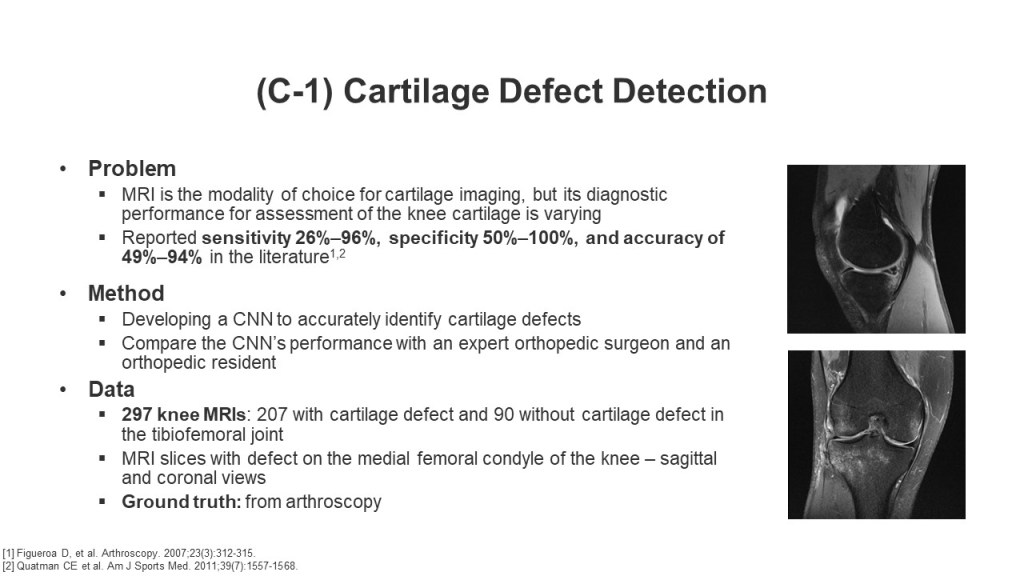

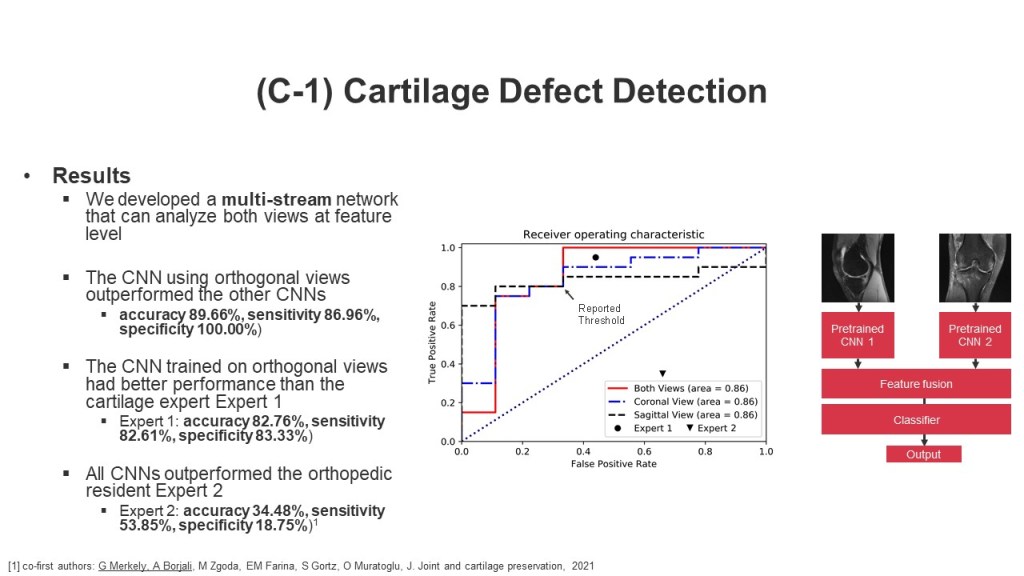

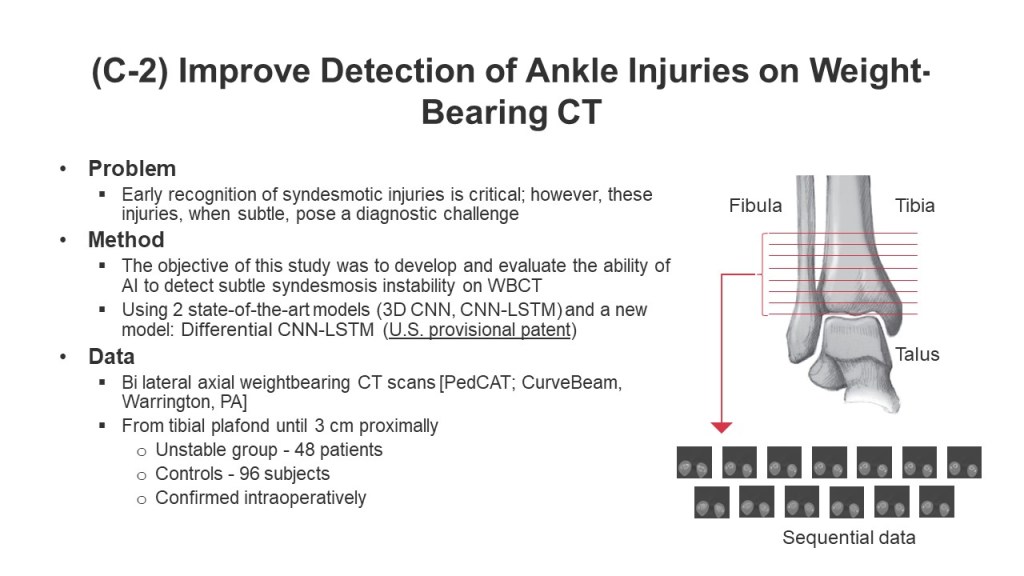

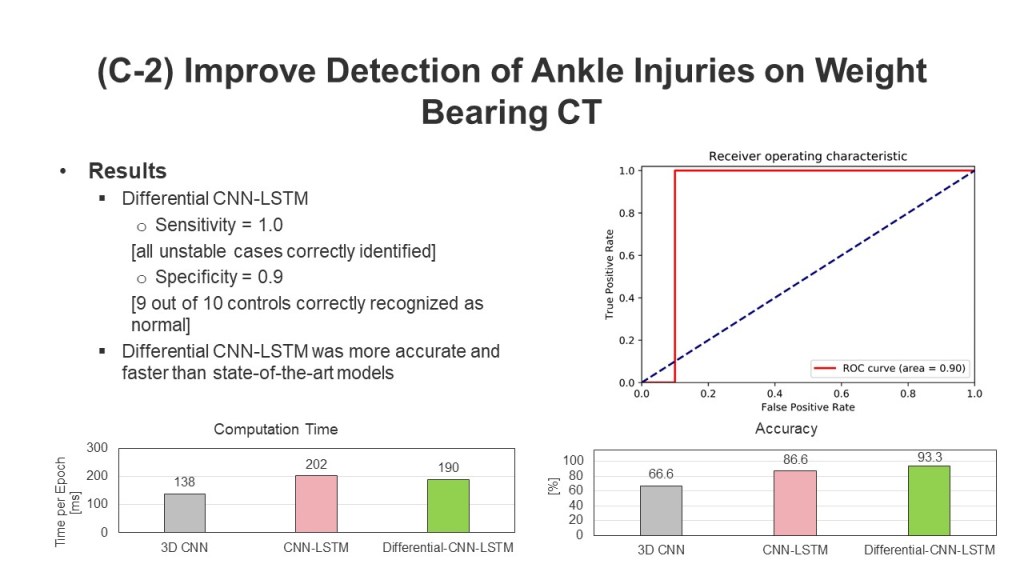

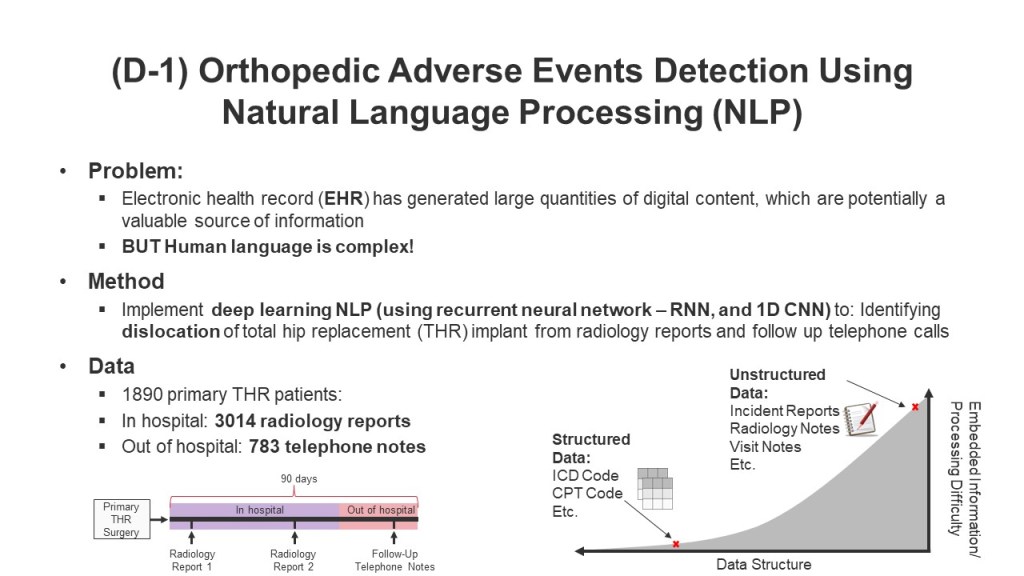

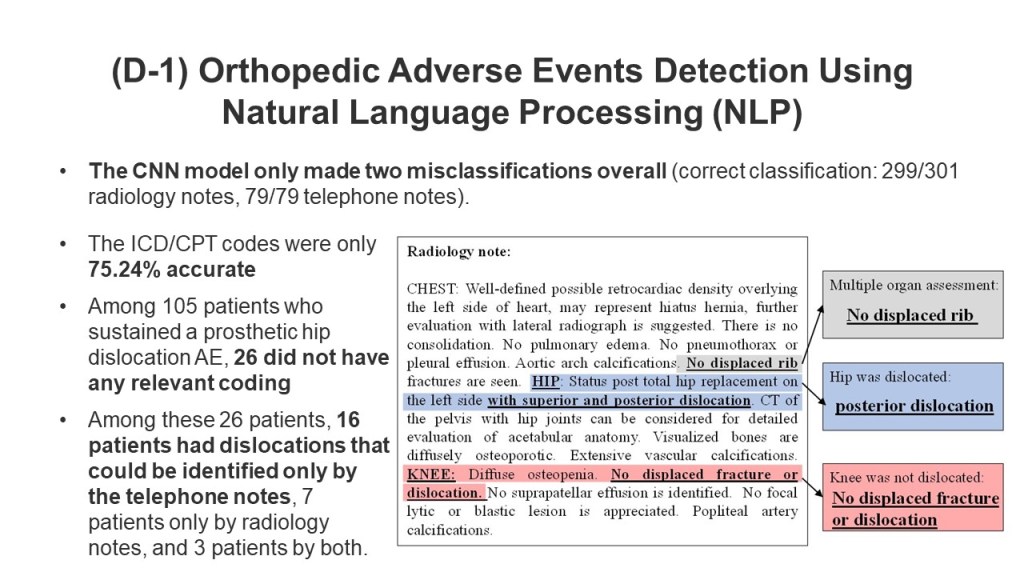

9. Artificial Intelligence for medical data analytics

I have extensive experience applying AI methods to analyzing medical data including X-Rays, MRI, CT-Scan, and Office Visit Notes. Please refer to my publications for more details. Here are the main categories of projects that I have done.

| My Expertise in AI | AI Model | Project Series |

| Data Driven Model (Conventional AI) | Conventional Machine Learning Models (KNN, SVM, DT, etc.) | A |

| 2D Image Analysis and Localization (Deep Learning) | 2D CNN, YOLO, R-CNN | B |

| 3D Image and Sequential Data Analysis (Deep Learning) | 3D CNN, CNN-LSTM, DCNN-LSTM (Novel patented model) | C |

| Natural Language Processing (Conventional + Deep Learning) | Conventional models (bag of words, n-grams, etc.) and novel deep learning models: RNN, Multi BIDI-LSTM, 1D CNN | D |

| Marker-Less Tracking and Pose Estimation (Deep Learning + Physics Based AI) | Time Series R-CNN, Attention + Physics Based AI | E |

Category:

Deep Learning, AI, Image Analysis, NLP, Data Visualization

Toolbox:

TensorFlow, PyTourch, Python, RapidMiner, SageMaker, DataBricks, Tableau, SQL, Time- Series Analysis

10. Intensity-based 2D-3D medical image registration

In this project, I studied the movements of the femur in patients suffering from ACL tears using dual-fluoroscopy imaging. I used CT scans to create a 3D model of the patients’ bones and then registered that model to 2D fluoroscopy images. I experimentally validated my algorithm using in-vitro testing.

This project was a part of a bigger project with the ultimate goal of designing a knee strap to help patients with an ACL tear.

Category:

Biomechanics, 2D-3D Image Registration

Toolbox:

CT Scans, X-ray fluoroscopy, Matlab

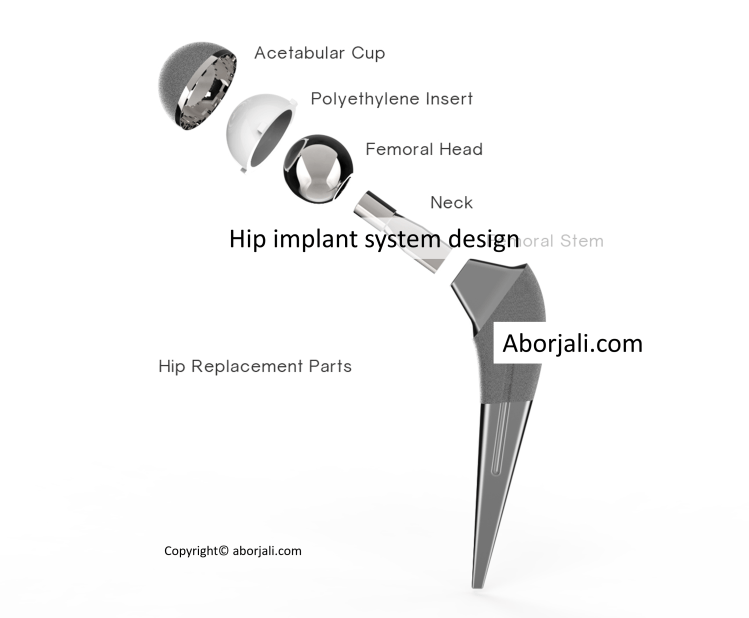

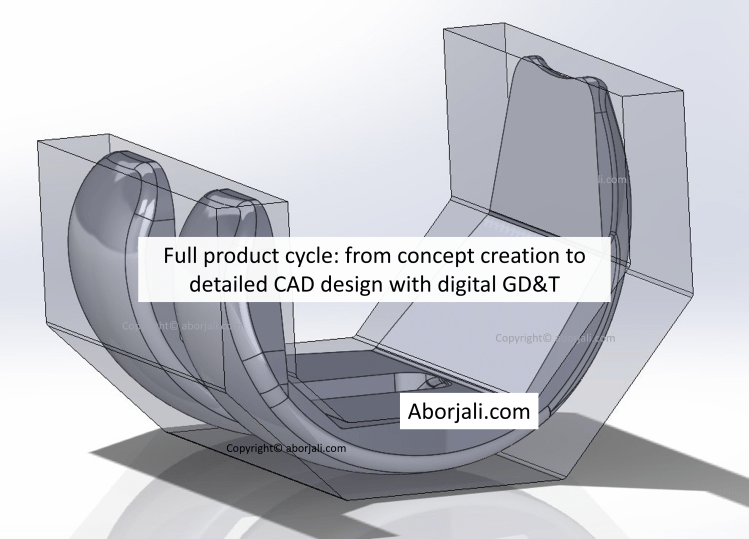

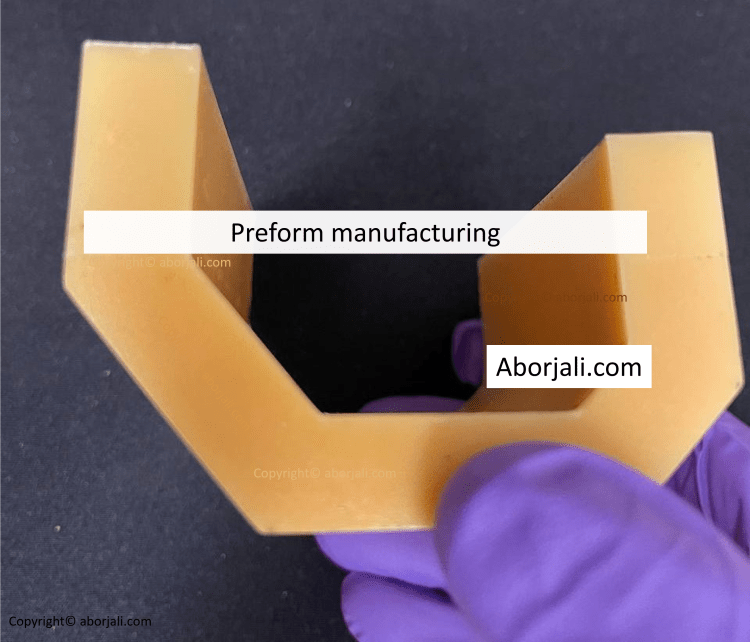

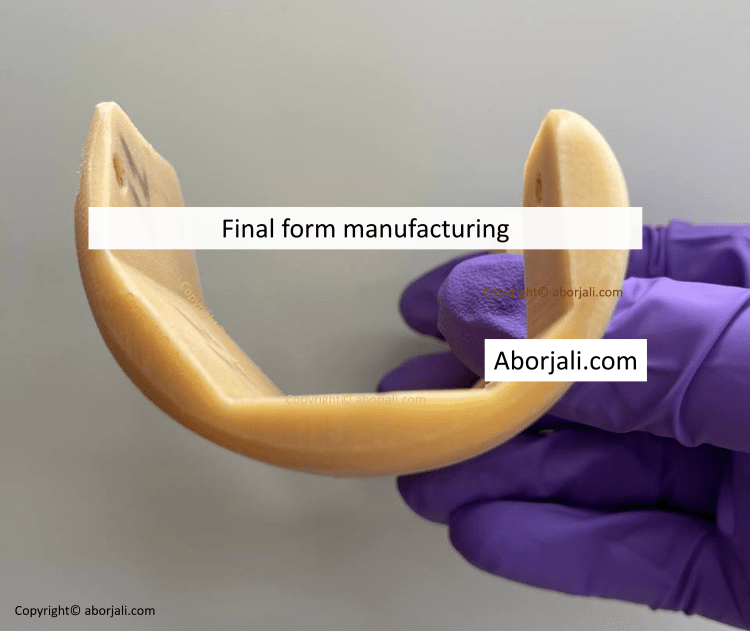

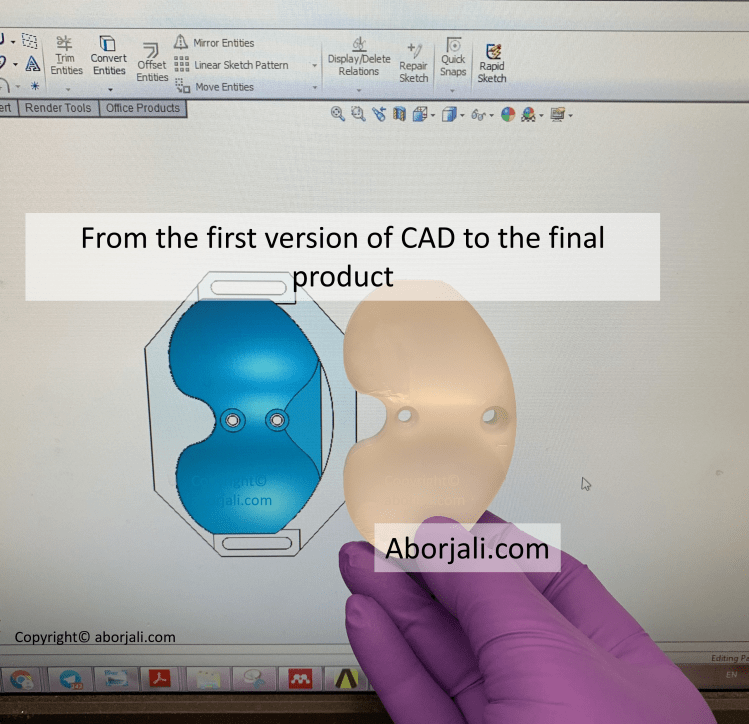

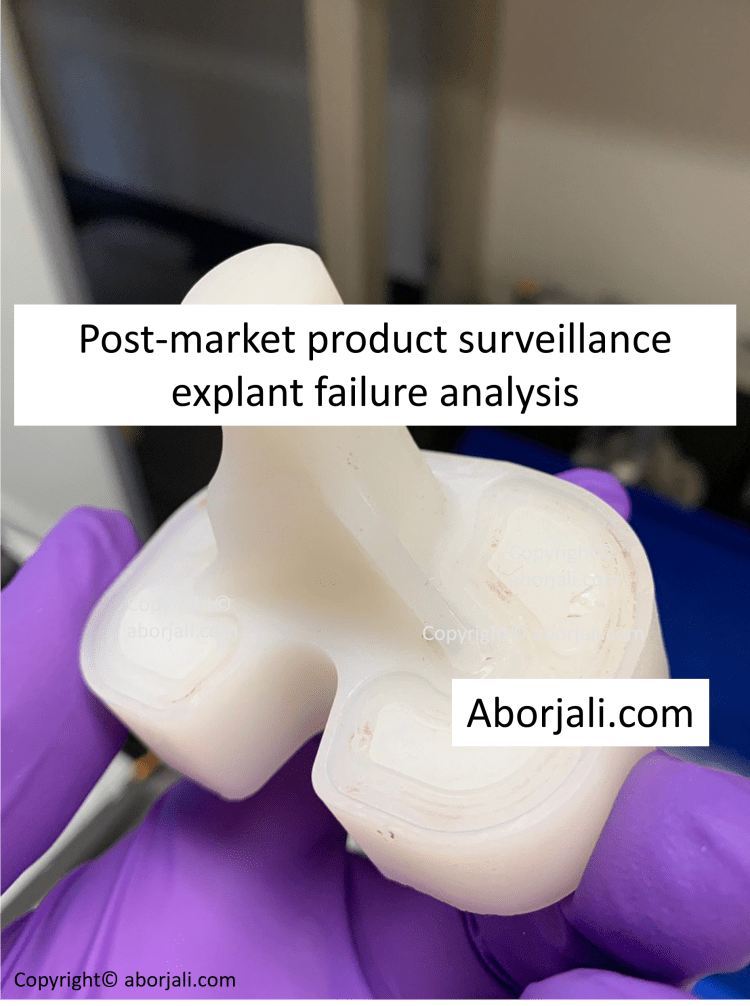

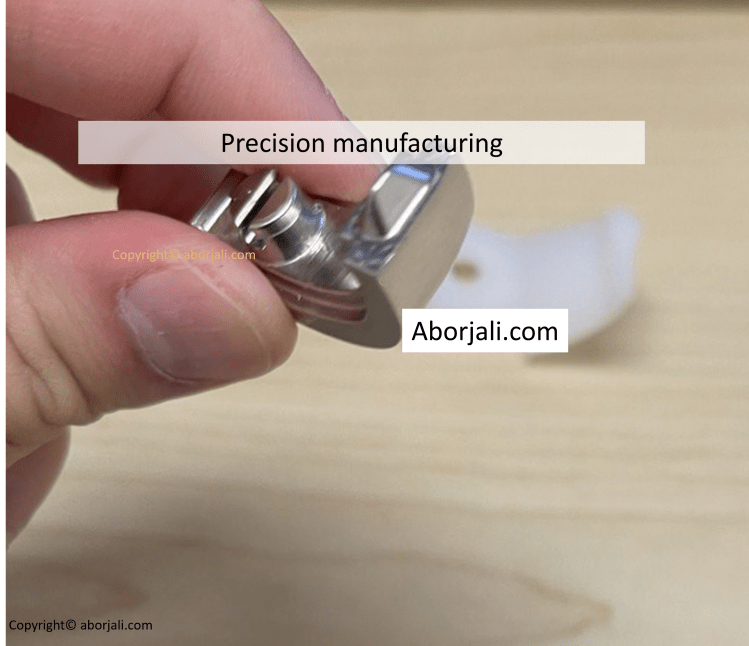

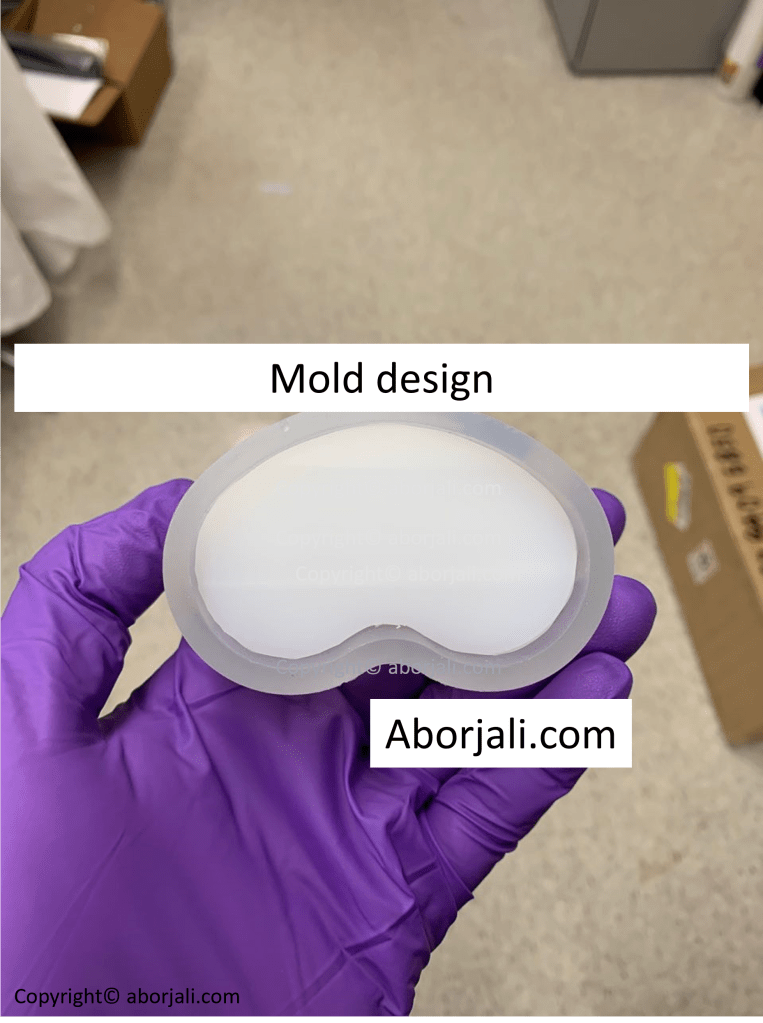

11. Medical Device Design

I have been involved in multiple FDA – approved Class III medical device developments as the lead R&D engineer.

Category:

Design, CAD/CAM, DFMA, Design Control, GD&T, Material Characterization, DOE, FDA 510(k)

Toolbox:

SolidWorks, Mold & Die Design, Extrusion Molding, FDA Submission, High Precision Machining, Sterilization and Packaging, Instrument Design, Design Validation and Verification

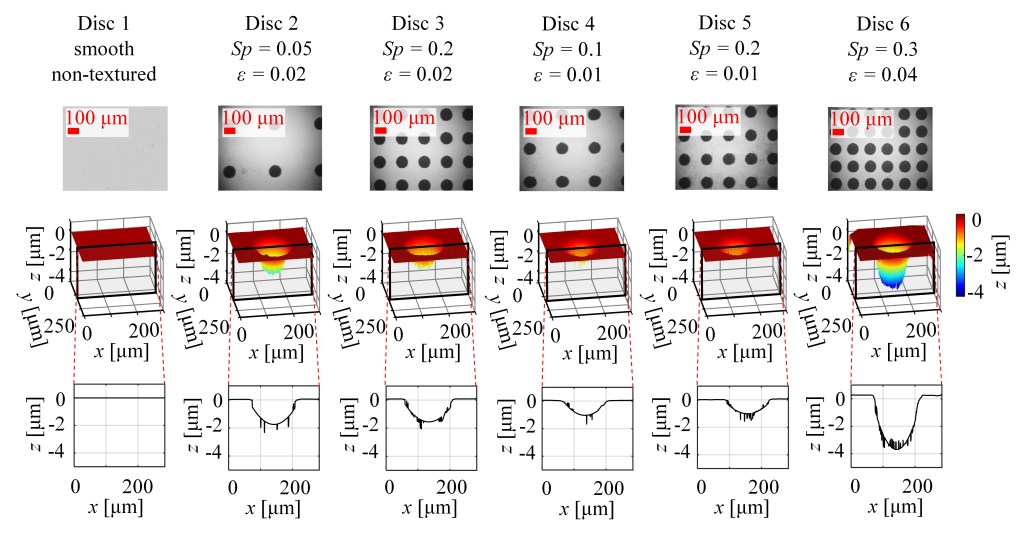

12. Microtextured prosthetic hip joints to improve longevity

Using a rigorous design and development process, starting with finite element analysis (FEA) and moving to multiple experimental studies, in this body of work I showed that adding a specifically designed patterned microtexture of concave “dimples” to a smooth CoCrMo surface via laser surface texturing significantly reduces polyethylene wear. Some of my major contributions to science as part of this project were characterizing the lubrication mechanism in prosthetic implants as a function of the surface texture design, quantifying the effect of surface texture design on polyethylene wear and CoCrMo corrosion resistance, and developing a data-driven model for polyethylene wear using machine learning.

Category:

Design, CAD/CAM, DFMA, Design Control, GD&T, Material Characterization, FEA, Biomechanics, Gait Simulation

Toolbox:

SolidWorks, Laser Surface Texturing, Machining, Wear Test, Python

Thank you for your attention 🙂